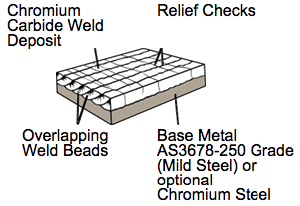

- Overlay Wear Plate

- Q&T Plates

- Ni-Hard Plates and Castings

- Hard Facing

- Tungsten Coating

- Work Hardening Wear Plates

Rating Wear resistance under controlled testing procedures by NATA certified and approved experts produced the above typical results. They included tests for abrasion and impact under both high and low stress conditions.

However any rating is dependent on a number of variables, such as the type of testing procedure adopted, the type of test carried out (high stress abrasion, low stress abrasion), the load applied in the test, speed variations, calibration anomalies etc. Results “in the field” do vary markedly according to the type of material, impact loads, speed of flow, support structures, consistency of flow and material, particle size, particle shape, correct machinery calibrations and other criteria.

Hardfaced Wear Plate has achieved results as high as 30:1 over mild steel and as low as 12.6:1.