- Bucket Elevators Belts

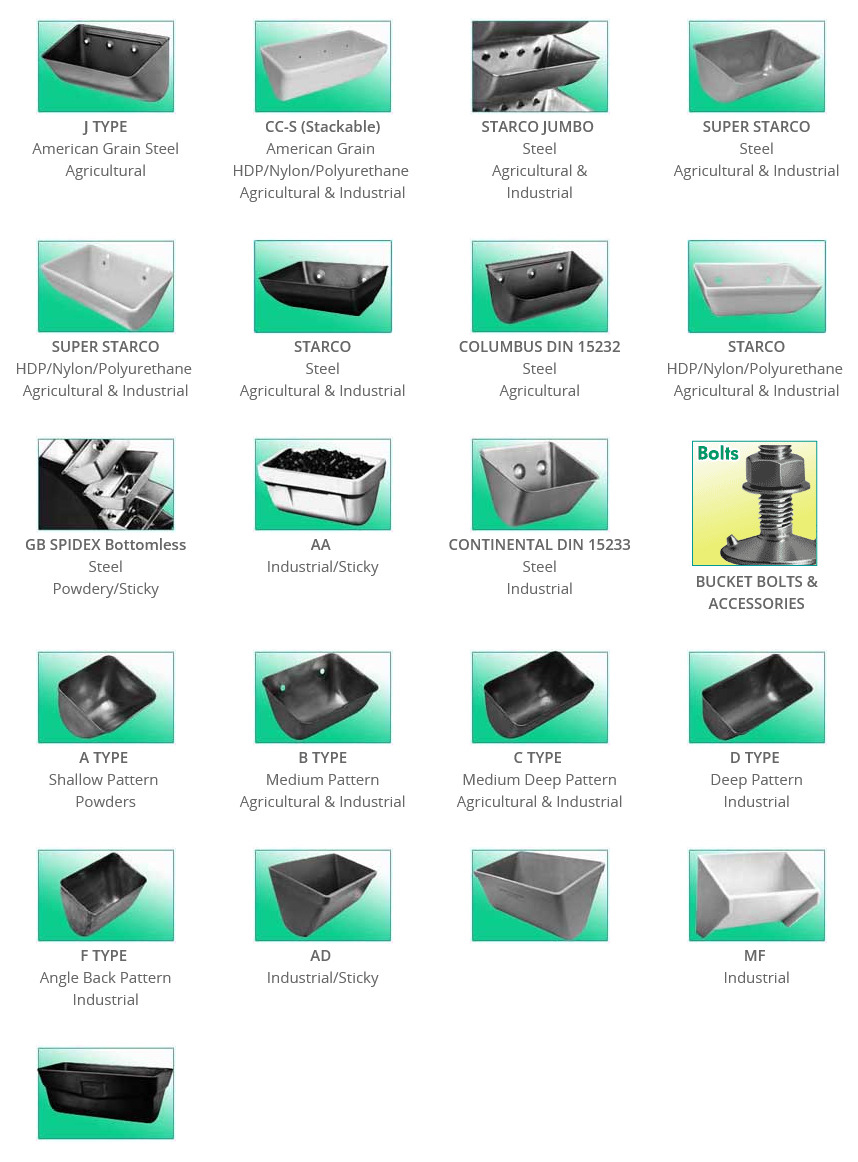

- Elevator Components – Buckets

- Elevator Components – Bucket Bolts

Centrifugal bucket elevators are most commonly used to convey all free-flowing, powdered bulk solids such as grains, animal feed, sand, minerals, sugar, aggregates, chemicals and more. They operate at high speeds, which throw the materials out the buckets into discharge throats by centrifugal force.

WEARCO NSW’s elevator design program can assist clients in almost all fields of industrial application for design and manufacture of new machines along with recommendations for retrofitting modification to increase performance of existing machines.