- Rock Breakers

- Chisel Tools

- Heavy Demolition Bits

Suitable for breaking concrete and all earth works in soft, non-stratified rock.

Chisel tool

![]()

Moil point tool

![]()

Blunt tool

![]()

WEARCO supply an extensive range of Chisel Tools for hydraulic breakers. We supply tools manufactured by ROCK, Indeco, Montabert, Rammer, Krupp Atlas Copco, NPK, Cat, Drago, Soonsan, Furukawa, Kent, Rotar, Arden, Yanmar and others.

The right choice of chisel tool is very important for the efficiency and durability of the breaker and tool.

Suitable for breaking concrete and all earth works in soft, non-stratified rock.

Chisel tool

![]()

Moil point tool

![]()

Blunt tool

![]()

Whether you are an independent contractor or a big construction company, we can cover your needs in heavy demolition bits for hydraulic hammers. We have access to any tool bit for your ground engaging demolition tools: moil points, chisels, blunt tools, asphalt cutters, ramming tools, tamping plates etc.

We can supply demolition bits for ALLIED, ALLIED STREET HAMMER, ATLAS COPCO, BOBCAT, BTI (TELEDYNE), CATERPILLAR, CHICAGO PNEUMATIC, D&A, GEHL, HUSKIE, INDECO, JCB, KENT, KOMATSU, KUBOTA, LIFTON, NPK, OKADA, RAMMER, ROCKBLASTER, SCHAEFF, SOCOMEC, SOOSAN, STANLEY, TOKU, TAKEUCHI and TRAMAC.

Quite often, our customers find it difficult to identify the exact make and model of the hydraulic hammer they use and therefore require help to order replacement demolition bits. WEARCO can provide assistance by utilising our extensive database of tool bits for hydraulic rock breakers.

Moil Point

Flat Chisel

Blunt Tool

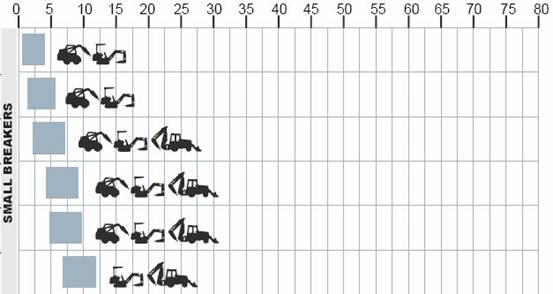

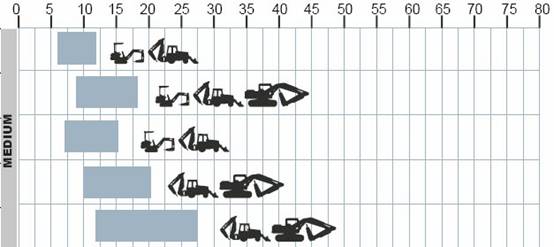

The breaker must be sized properly for both the work it will do and the carrier on which it will be mounted. The type of work is the most critical factor in choosing the breaker size.

After considering the application work, the carrier on which the breaker will be installed needs to be considered. Hammer manufacturers have assigned a ‘Recommended Carrier Weight’ range to each breaker. If the operating weight of the carrier falls within this range, the carrier will safely handle the model of breaker. If the desired breaker falls outside of the recommended carrier weight range, the carriers lifting capacity and oil flow will need to be verified to ensure a proper fit.

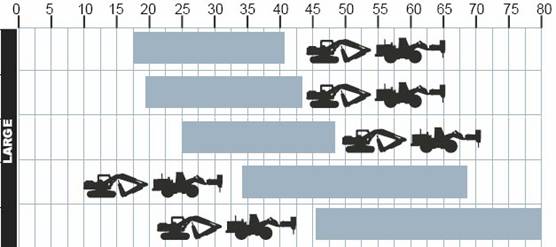

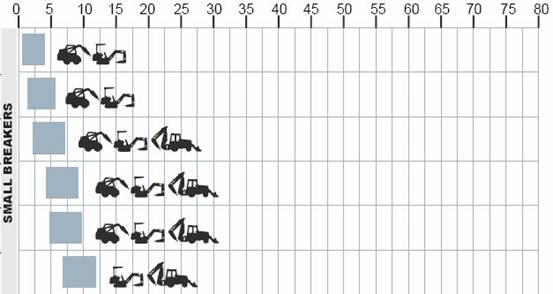

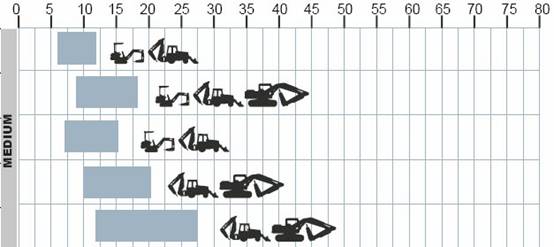

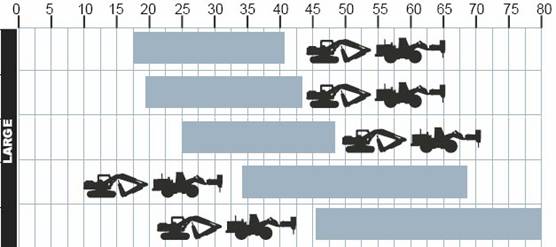

Please refer to the following charts ‘Sizing the Breaker’ which outlines the recommended carrier weight range.

HOW TO USE THESE CHARTS

Carrier Weight in Metric Tons

Carrier Weight in Metric Tons

Carrier Weight in Metric Tons

Suitable for breaking concrete and all earth works in soft, non-stratified rock.

Chisel tool

![]()

Moil point tool

![]()

Blunt tool

![]()

Whether you are an independent contractor or a big construction company, we can cover your needs in heavy demolition bits for hydraulic hammers. We have access to any tool bit for your ground engaging demolition tools: moil points, chisels, blunt tools, asphalt cutters, ramming tools, tamping plates etc.

We can supply demolition bits for ALLIED, ALLIED STREET HAMMER, ATLAS COPCO, BOBCAT, BTI (TELEDYNE), CATERPILLAR, CHICAGO PNEUMATIC, D&A, GEHL, HUSKIE, INDECO, JCB, KENT, KOMATSU, KUBOTA, LIFTON, NPK, OKADA, RAMMER, ROCKBLASTER, SCHAEFF, SOCOMEC, SOOSAN, STANLEY, TOKU, TAKEUCHI and TRAMAC.

Quite often, our customers find it difficult to identify the exact make and model of the hydraulic hammer they use and therefore require help to order replacement demolition bits. WEARCO can provide assistance by utilising our extensive database of tool bits for hydraulic rock breakers.

Moil Point

Flat Chisel

Blunt Tool

The breaker must be sized properly for both the work it will do and the carrier on which it will be mounted. The type of work is the most critical factor in choosing the breaker size.

After considering the application work, the carrier on which the breaker will be installed needs to be considered. Hammer manufacturers have assigned a ‘Recommended Carrier Weight’ range to each breaker. If the operating weight of the carrier falls within this range, the carrier will safely handle the model of breaker. If the desired breaker falls outside of the recommended carrier weight range, the carriers lifting capacity and oil flow will need to be verified to ensure a proper fit.

Please refer to the following charts ‘Sizing the Breaker’ which outlines the recommended carrier weight range.

HOW TO USE THESE CHARTS

Carrier Weight in Metric Tons

Carrier Weight in Metric Tons

Carrier Weight in Metric Tons